There are a lot of assists that we can offer for industrial mixer cleaning on discharge and cleaning of the machine.:

Let me state some obvious and maybe not so obvious things:

- A drop bottom mixer will clean out better on discharge than a port discharge or a valve.

- The smaller the diameter of the mixer, the better a drop bottom will clean out because of a steeper angle coming into the discharge opening. On bigger machines, the angle gets down to 10 degrees, and material will sit along the sides of the discharge. Making doors bigger will help if it is not at the expense of having the discharge leak. Look at a double rotor in the same volume and it may have a better angle.

- Vibrators will help. The machine has to be installed so it can move. It can be done with a mixer on load cells.

- Trying to blow out “automatically”, doesn’t work well. The problem is that when you get the nozzle clear of the rotor, the distance is so far that air loses velocity. The same is true of built-in power sprayers. If you give a person a wand for air or a power spray, the person can get close enough to be effective.

- One possibility it to have removable wash balls, or similar. With CIP, it is difficult to clean the nozzle itself. Removing it lets it be cleaned outside. It can be a quick disconnect system.

- Access without getting inside the mixer is necessary for comfort and safety. We have a design of side door that can be in the mixing zone without leaking.

Industrial Mixer Cleaning can be easier based on the design of your mixer. We have one application where the mixer is completely inaccessible, and it mixes a sticky ingredient. We made the mixer round, and impregnated it with Teflon, and it cleans itself sufficiently for this application.

This idea or some variation can be use for product sticking on the sides or dust above the rotor. We have UHMW milled to wrap the paddles for a distance to stop the buildup. Polishing carbon steel will make it clean better. We polish quite a few AR machines.

Teflon impregnation and electro-polish both are good to reduce sticking and improve industrial mixer cleaning on discharge. We use Inhibcote Impregnation, not Silverstoning, because Silverstoning chips off.

Inhibcote is green or brown color, food grade. The color can wear off but the suface is still slippery. It does not stand up to high temperatures or high abrasion. We’ve had success when waxes, molasses, etc. builds on the backs of paddles. Makes power washing, brushing, or scraping a lot easier. Inhibcote is a process licensed to coaters by Dupont and can be done on carbon and stainless steel machines.

Electropolishing used to be expensive but that is no longer true. It makes cleaning easier.

A method of production of colors is usually to go from light to dark and then clean for a switch over. The cleaning can be sweeping with a corn broom to a complete wipe down.

Purges can work for a change over. I would recommend the purge be at least 100% of rotor volume. We know you want to use at little as possible but a few pounds does nothing. The purge material should have some abrasive quality e.g. sand, salt, granulated sugar.

Our mixer is the easiest mixer with an internal agitator to clean. Loose material does not lie on the rotor like some vertical mixers. There are long and short paddles, and there is access to the wall for 120 degrees over the short paddle. With all helical drives, the rotor can be move manually. The sides are clear and the bottom can be clear to sweep to a port. Our discharge doors stay open on a lockout, and we provide the access if the mixer is not buried.

Bring us your problem and let us work with you to solve it.

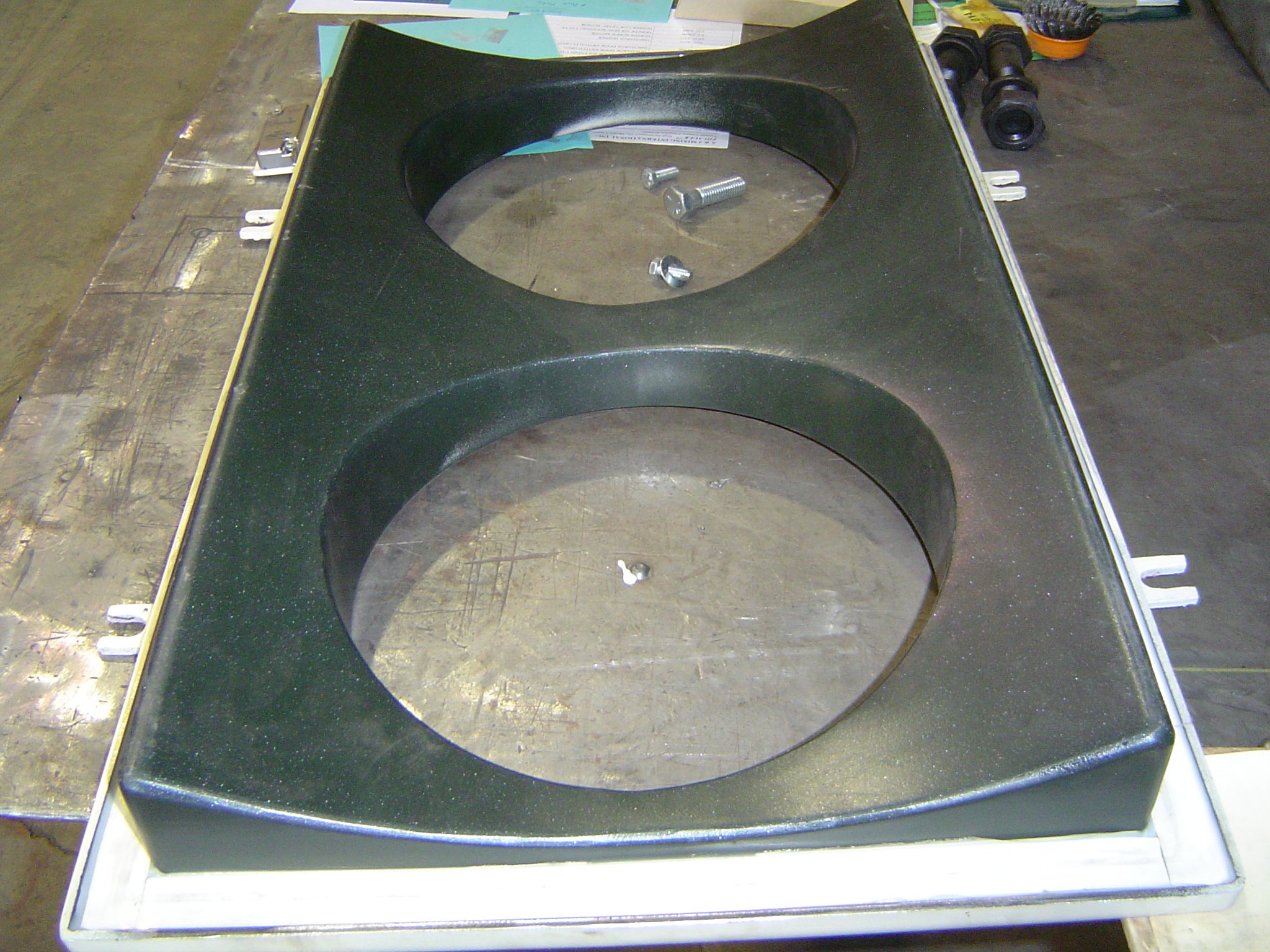

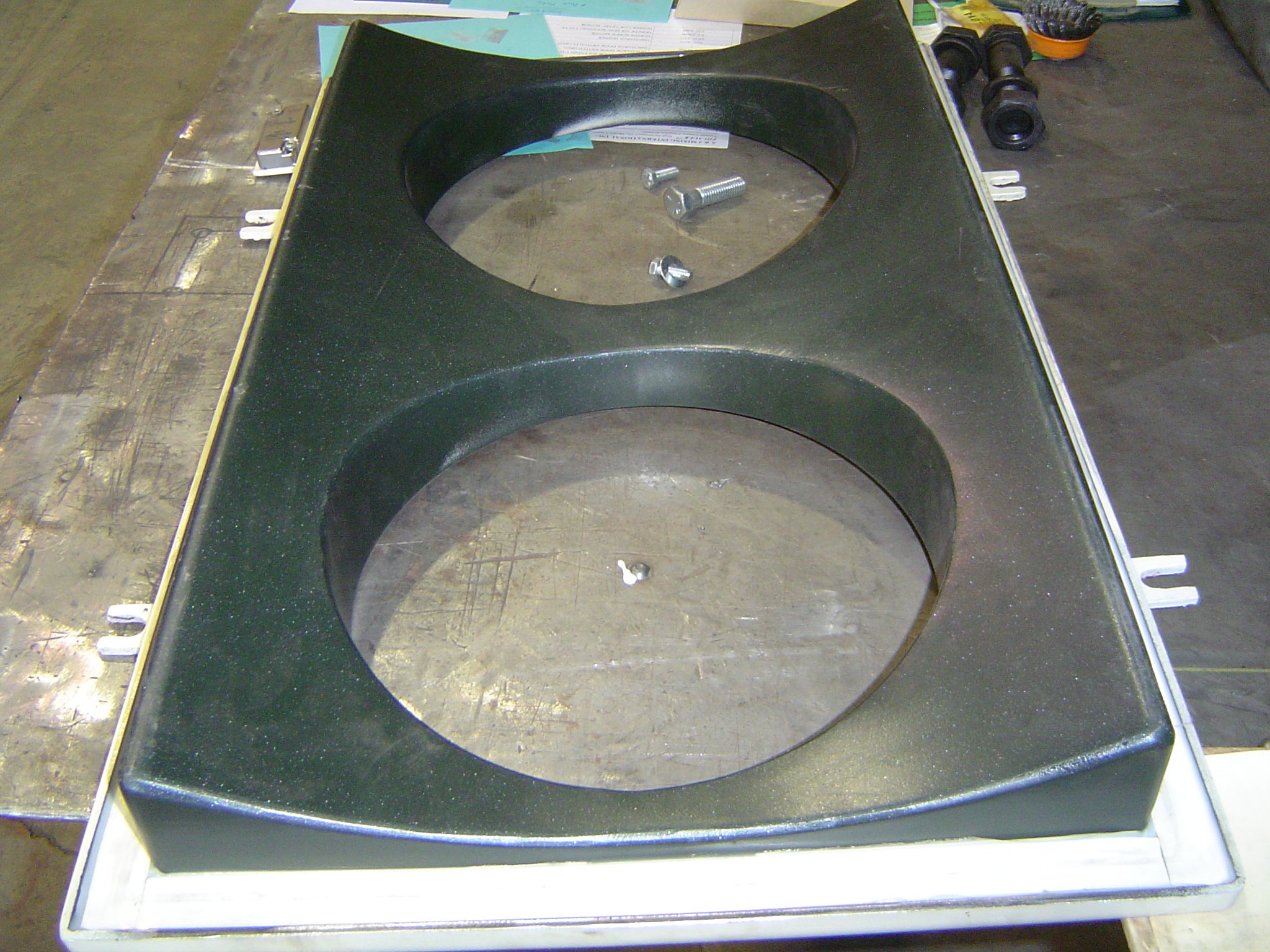

The PHLAUER™ mixer is inaccessible and is designed to be “self-cleaning”

in terms of handling a sticky ingredient and operate for several years.

The mixer is cylindrical with close rotor clearance, and impregnated with Teflon.

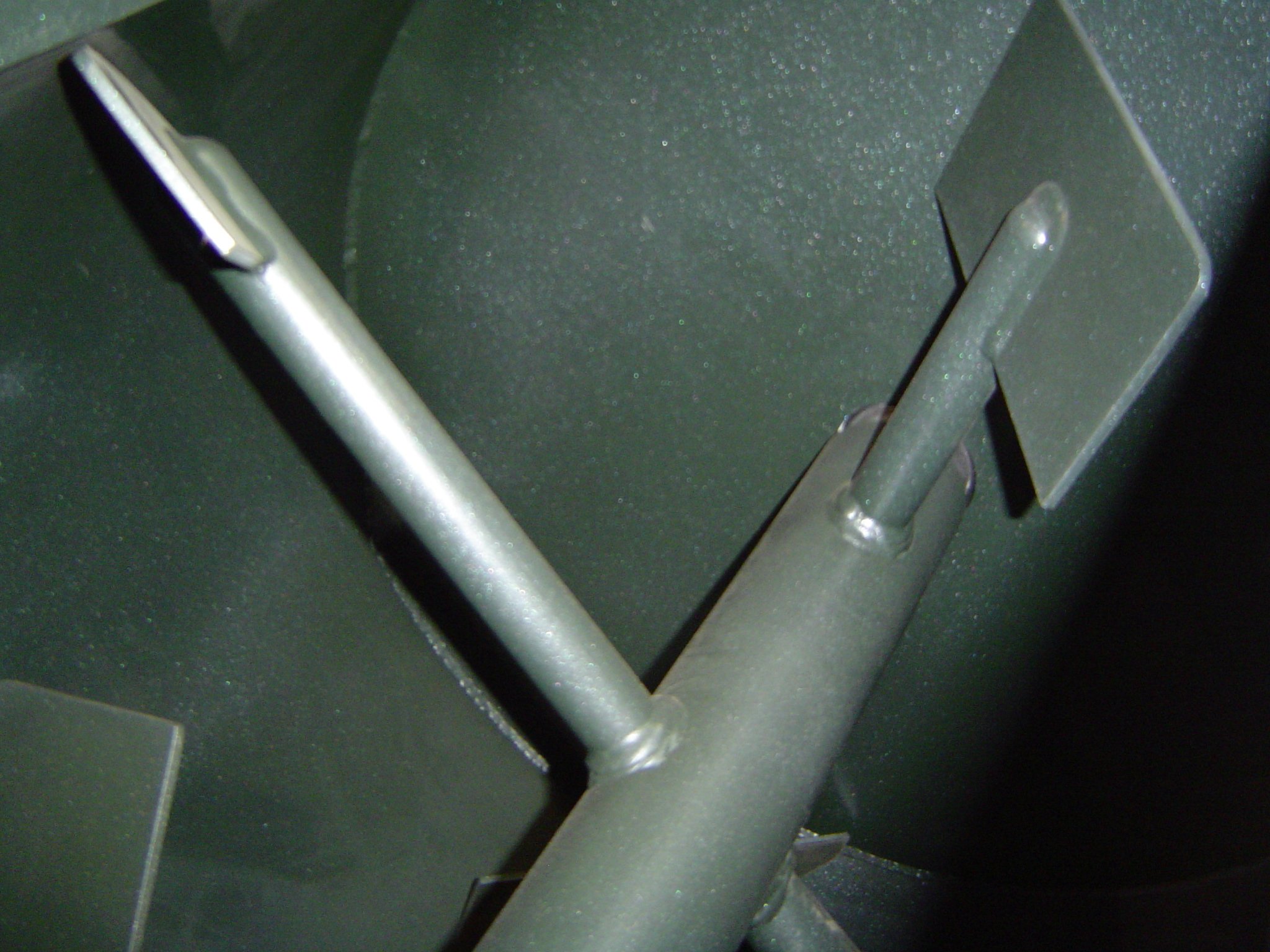

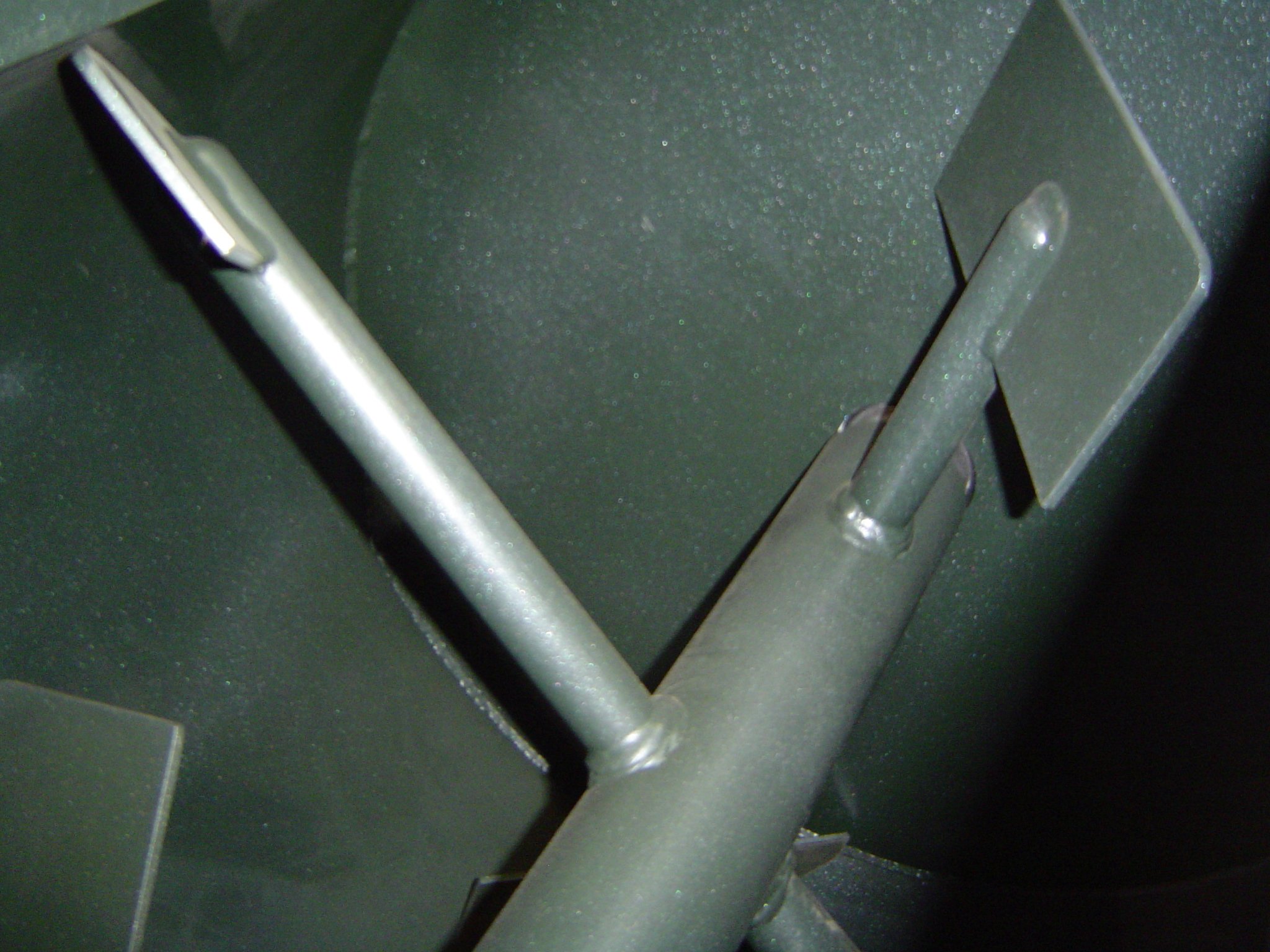

Inhibcote Teflon Impregnation on Carbon Steel

Cleaning Doors in Mixing Zone

SMICO COMPANIES -

SMICO COMPANIES -

Optimize Your Production

Optimize Your Production

We love what we do

We love what we do